Installing new garage floors can change the whole appearance and capability of your garage space. Whether you are forming your garage, a workshop, a showroom for your car, or just elevating the storage space, you need the right floor. However, many family owners or even experts make silly garage flooring mistakes during installation, and errors that can shorten the floor’s lifespan or later cause disappointing issues.

In this comprehensive blog, we can review the top garage flooring installation errors to avoid when installing garage floors and ensure that your investment is long-lasting, functional, and visually attractive.

Common Garage Flooring Mistakes to Avoid When Installing

Here are the significant garage flooring mistakes that should be averted while installing garage floors as follows:

1. Not doing the concrete nicely

Why is this one of the garage flooring mistakes?

Your garage floor may appearance clear, but if it isn’t always nicely prepared, the great coatings or tiles will not adhere correctly. Residual oil stains, dirt, old paint, and moisture can cause adhesives to fail or epoxy coatings to peel premature.

How to Avoid:

- Degrease and clean very well using a high-quality degreaser.

- Etch or grind the floor to create a texture for coatings to bond.

Test for moisture using calcium chloride or a plastic sheet. If concrete sweats or has a high moisture content, a remedy is necessary before installing the floor.

2. Skipping restoration on damaged concrete

Why is this one of the garage flooring mistakes?

Small cracks and chips can also look harmless, but they can get worse with time and result in structural instability or floor defects. Coatings or tiles put on the broken concrete will further exacerbate garage floor durability issues.

How to Avoid Garage Floor Coating Problems:

- Fill cracks with epoxy or polyurethane sealants.

- Use a concrete patching compound for chips or holes.

- Smooth out uneven surfaces to ensure a proper installation base.

3. Selecting the incorrect ground for your desires

Why is this one of the garage flooring mistakes?

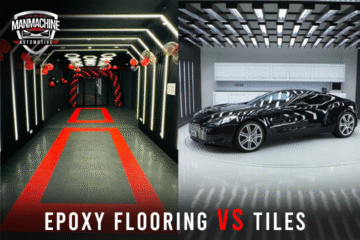

Not all garage floors are equal. Each type, such as epoxy, tiles, mats, or polyaspartic coatings, has advantages and disadvantages. Any wrong choice can lead to poor performance in selective storage situations.

How to Avoid:

Consider how the garage has to be used, such as a heavy system, car repair, foot traffic, oil exposure, and many others.

Research on different garage types:

- Epoxy is best for durability and appearance, but requires proper preparation.

- Interlocking tiles are simple to put in, but might capture moisture beneath.

- The roll-out mats are speedy, but much less permanent.

- Polyaspartic coatings treat quickly and oppose UV harm better than epoxy.

4. Ignore the state of temperature and moisture circumstances

Why is this one of the garage flooring mistakes?

Many coatings and glues require specific environmental situations to cure correctly. Ignoring them may cause bubbling, peeling, or inappropriate bonding.

How to Avoid:

- Always study the manufacturer’s instructions on the perfect temperature and humidity ranges.

- Avoid installation during raining or freezing/warm weather.

- Use a dehumidifier or fans if vital to control the environment during installation.

5. Knowing the time and labour participation

Why is this one of the garage flooring mistakes?

Garage floors aren’t an instant weekend DIY assignment, especially when working with coatings such as epoxy or polyaspartic. Hurrying can lead to errors like improper adhesion, air bubbles, or uneven finishes.

How to Avoid:

- Plan for good enough guidance and treatment (frequently 2-five days).

- Follow a step-by-step technique, and do no longer cut the corners.

- If you’re uncertain, take into account hiring a professional installer to work well to do the job well.

6. Do not use the correct tools or products

Why is this one of the garage flooring mistakes?

Trying to use generic tools or low-quality products can lead to a messy finish or poor performance. For example, using a cheap roller of epoxy can leave lint on the floor.

How to Avoid:

- Invest in epoxy-rated rollers, brushes, and squeegees.

- Use products of reputable brands, especially those specifically designed for garage floors.

- Avoid household paint – use only dedicated garage floor coatings.

7. Ignorance of drainage or sloping issues

Why is this one of the garage flooring mistakes?

A flat or poorly sloping garage floor can gather water, damaging it and increasing the risk of sliding. It can also cause coatings to be used unevenly.

How to Avoid:

- Check the correct drainage or floor pitch before installing the floor.

- If necessary, reslope the floor or install trench drains to remove water.

- Consider water repellent flooring options such as PVC tiles or waterproof coatings.

8. Apply a very thick or thin coating

Why is this one of the garage flooring mistakes?

The thickness of the coating is essential. If it is too thick, the floor can crack or be unevenly treated. If it is too thin, it will result in poor safety and premature wear.

How to Avoid:

- Follow the manufacturer’s specifications with the correct application thickness.

- Use measuring tools or notched squeegees to maintain stability.

- Apply in several thin layers instead of a thick.

9. Forgetting about expansion gaps (for tiles)

When using interlocking tiles or rigid floors, the lack of expansion gaps can cause buckling or cracking when the temperature changes.

How to Avoid:

- Leave a difference of 1/4-inch between the floor and the garage walls.

- Use the edge trim pieces to allow for expansion and contraction.

- Avoid installing tiles extremely tightly against each other.

10. Not sealing the floor when needed

Why is this one of the garage flooring mistakes?

Even after a successful installation, some garage floor types require a topcoat or sealant to extend their life and protect them from wear, chemicals, and UV rays.

How to Avoid:

- Understand if your selected floor (especially epoxy or concrete stain) requires a clear topcoat.

- Use UV-resistant sealers for garages that get too much sunlight.

- Do reapplication of the sealant after every couple of years based on wear.

11. Installing it on a moisture-prone slab or damp

Why is this one of the garage flooring mistakes?

Garage floors subjected to hydrostatic pressure or water can destroy coatings or cause matte/tiles to lift and change shape.

How to Avoid:

- Perform a moisture test before installation.

- Use steam barriers or moisture reduction systems if necessary.

- Consider breathable options as such as modular tiles for high moisture areas.

12. Overcomplicating DIY projects

Why is this one of the garage flooring mistakes?

Some people try complex systems such as metallic epoxy floors or tailored patterns without the experience of DIY, resulting in botched designs, wasted materials, and expensive redos.

How to Avoid:

- If you are a DIYer, stick to simple, beginner options.

- See tutorials, programs, and read user reviews for guidance.

- When you doubt, consider professionals for a high-end finish.

13. Ignoring maintenance after installation

Why is this one of the garage flooring mistakes?

No matter how durable your floor is, it must be maintained. Negligence leads to a dull finish, spots, or rapid deterioration.

How to Avoid:

- Clean the floor regularly with a non-acidic cleaner.

- Avoid pulling heavy equipment without mats or safety.

- Reseal or recoat the base based on the recommended maintenance plan.

14. Unable to plan around the garage fixtures

Why is this one of the garage flooring mistakes?

Floors can result in weird seams, uneven weight distribution, or later cutting without thinking about where cabinets, lifts, or gear will go.

How to Avoid:

- Before you begin, plan the floor layout mainly for tiles or patterns.

- Mark out locations for heavy devices or storage.

- Use industrial-grade flooring below concentrated weight regions.

15. Manufacturers who ignore commands

Why is this one of the garage flooring mistakes?

Each product is unique. Thinking about all the manufacturers of epoxy or tiles can lead to disaster. You can end up with curing issues, raised tiles, or even chemical reactions.

How to Avoid:

- Read the follow the entire instruction manual properly.

- Do not mix brands until they are compatible.

- Be aware of the working time, cure time, and coverage limits.

Conclusion

Installing garage flooring can be significant, and it would be like a reward and an upgrade of your property. The way to a successful, long-lasting outcome lies in preventing basic garage flooring mistakes such as inadequate surface prep, wrong product choices, skipping moisture assessments, and neglecting environmental conditions.

By taking the time to plan, prepare, and invest in high-quality garage flooring, such as Manmachine Automotive Garage Flooring, you will not only get the sturdiness and performance of your garage floor but also safeguard yourself from further complications and unwanted expenses.

FAQS

Q1. What is the pleasant choice for a Garage Floor for a DIY setup?

Interlocking tiles or rollout mats are considered one of the best DIY garage flooring options. They do not require glue or processing time and can be installed with minimal tools.

Q2. How long will I wait after installing the epoxy before using my garage?

Most epoxy coatings require at least 72 hours of curing before heavy usage. Light foot traffic can be allowed after 24 hours, but wait for a full 3-5 days before driving it.

Q3. Can I install garage floors during monsoon or winter?

It is not recommended until the garage environment is completely climate-controlled. High moisture or low temperature can prevent proper treatment and lead to adhesion problems.

Q4. Do I have to seal the concrete before installing tiles or mats?

You do not need to seal before tile or food installation, but you should make sure the concrete is dry and clean. Sealing is more critical before epoxy or stain coatings.

Q5. How long does the garage flooring usually last?

It depends on the type:

- Epoxy: 5-10 years

- Polyaspartic: 10-15 years

- Interlocking tiles: 10+ years

- Mats: 3-5 years

Proper maintenance can extend the lifespan.

0 Comments