Selecting the correct finish can lead you into a dilemma. That’s why we’re here to reduce the noise and help you finally compare epoxy garage floor coatings with their toughest competition. We’re breaking down the polyaspartic vs epoxy debate so you can have a dilemma.

You’re finally ready to give your garage or basement the upgrade it deserves, but you cannot do the comparison of epoxy garage floor coatings with others. You’ve heard of epoxy floor coverings for garages, but what about these new options as polysapartic?

That’s why we’re here to reduce the noise and help you finally compare epoxy garage floor coatings with their toughest competition. We’re breaking down the polyaspartic vs epoxy decision on the best garage floor coating for your home without needing a chemistry degree.

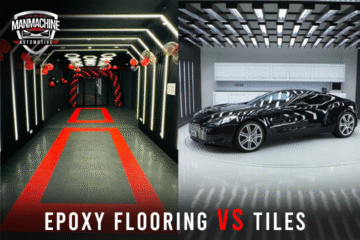

Polyaspartic vs Epoxy Comparison

Here is a complete comparison between the epoxy and polyaspartic as follows:

Compare Epoxy Garage Floor Coatings

At their core, both materials are high-performance resins designed to protect your concrete.

The Conventional is an Epoxy Floor

So, what is epoxy flooring?

Think of epoxy in the form of true works. It has been used for almost years and is used in everything from industrial warehouses to residential garages.

Epoxy is formed by mixing a resin and a hardener, which forms a super-hard, plastic-like shell connected to concrete.

Here is a table showcasing the pros and cons of an epoxy floor.

Epoxy Pros (Advantages) |

Epoxy Cons (Disadvantages) |

| Reasonable: Usually, the most pocket-friendly choice for the initial budget. | Long processing time: The curing procedure needs a few days (up to one week), which states that the garage is useless for an extended period of time. |

| Good durability: When healed, it forms a very stiff surface that can withstand high traffic and most effects.

|

Zero UV stability: When exposed to sunlight, it turns yellow and fades, which lessens its use in places with some natural light. |

| Chemical resistance: Amazing resistance to oil and grease, mainly focused on battery acids. | Brittle/Rigid: Doesn’t have flexibility, forming it vulnerable to cracks, chipping, and peeling when concrete moves or freezes. |

| High adaptation: Accessible in a vast variety of colours, finishes and beauty options. | Temperature sensitivity: An exact temperature window (usually above 50 ° F) for installation is required, and it cannot be applied well in cold weather. |

Modern Upgrading is Polymeric

Polysapartic is usually classified as belonging to the polyurea family of coatings, which is why you often see the phrase polysapartic polyurea vs. epoxy floors.

Polysapartic is a very advanced version of polyuria. It is designed to remove all traditional weaknesses in epoxy, which provides a more flexible, sharp, and UV-resistant finish.

When a professional discusses the best epoxy options for the floor, they will have a high-quality polyurethane floor cover.

Here is a proper table that showcases the pros and cons of polyaspartic.

Polyaspartic Pros (Advantages) |

Polyaspartic Cons (Disadvantages) |

| Fast installation: Often provides a complete, vehicle-ready floor in one day, and minimises downtime. | High costs: It is usually more expensive than a standard epoxy coating. |

| Extreme flexibility: Less stiff than epoxy, it is very resistant to cracks and peeling from temperature shift (hot/cold concrete movement). | Complex for DIY: Due to its swift treatment time (“limited working hours”), the application is complex and should be performed by skilled professionals. |

| UV stability: When exposed to direct sunlight, it will not turn yellowish, faded, or “amber,” making it perfect for garage and external applications. | Acid sensitivity: This is opposed to most chemicals, as it can lead to rusting with heavily concentrated acidic fluids, such as battery acid. |

| Wide temperature range: It can be installed in a very cold (below freezing) or very warm ambience, permitting year-long operation. |

Time is Your Most Valuable Asset

This is the number one, make-or-break difference between the two systems. If you want your life back fast, pay attention here.

Feature |

Epoxy (The Slow Wait) |

Polyaspartic (The Quick Fix) |

| Installation Time | Requires days. Each coat takes up to 24 hours to cure, often stretching the job to 3–5 days. | It can be done in one day. It cures in hours, not days. |

| Vehicle Ready | 3 to 7 days. Your cars, tools, and life are stuck outside. | 24 to 48 hours. You get your garage back almost immediately. |

| Application Flexibility | Hates cold weather. If it’s too chilly, the epoxy won’t cure properly. | Loves all weather! It can be applied in extreme heat or cold (even below freezing). |

| Costing | ₹40 to ₹150 per sq. ft. (approx.) from getting it from a basic industry, and also the flake finish/self-levelling affects the price, but around ₹300 per sq. ft. if you are getting it done from a high-end 3D designer. | ₹100 to ₹350 per sq. ft. (approx.) if you are getting it done from a high-end place with premium products. |

The key takeaway is speed. If you choose a premium system like polyaspartic coating vs epoxy, you definitely minimise downtime. For busy homeowners, the simple fact that you can get your space done in a single day makes the garage floor epoxy vs. polyaspartic debate an easy win for the modern coating.

Durability Against Fading, Cracks, and Hot Tires

If you’re paying for the best garage floor finish, you would definitely want it to last. This is where Polyaspartic truly shines and offers superior value over time.

The War Against the Sun (UV Stability)

- Epoxy: It has a fatal flaw: it hates the sun. When exposed to UV rays (even just the sunlight coming through your garage door), it yellows and fades. It is a process known as ambering. It’s simply not the right choice if your garage gets any sunlight.

- Polyaspartic: It’s completely UV stable. It will not yellow or fade. The colour you choose today is the colour you’ll have ten years from now.

The Fight Against Cracks (Flexibility)

Concrete naturally expands and contracts with temperature changes.

- Epoxy: It’s rigid and brittle. The epoxy can’t stretch when the concrete moves, leading to cracks and ugly peeling (delamination).

- Polyaspartic: It’s incredibly elastic and flexible. It moves with the concrete, creating a much stronger, long-lasting bond that resists cracking. This superior performance is why many professionals refer to these systems, which sometimes reference specific formulas like a “Poly Rovers Coat“, as the best garage floor coating.

Why We Don’t Recommend Garage Floor Paint vs Epoxy

Many confuse high-quality coatings with basic floor epoxy paint (often the cheap DIY kits). Paint offers little to no protection. Even the best epoxy floor coatings for garages provide basic safety, but they still don’t match the flexibility and UV stability of Polyaspartic.

Which Investment is Right for Your Home?

Choosing between a polyurea floor coating vs epoxy is really about balancing your budget against your long-term goals.

| Choose Epoxy If | Choose Polyaspartic If. |

| Budget is your only focus. (It has a lower upfront cost.) | You need a 1-day installation and can’t handle extended downtime. |

| Your space is 100% indoors (like a dark basement) with no sun exposure. | Your garage door lets in direct sunlight (no more yellowing!). |

| You’re okay with re-coating or touching up the floor every 3-5 years. | You want the absolute best garage floor finish that is flexible and lasts 15+ years. |

While epoxy flooring for homes has been a staple, the truth is that the advanced chemistry of Polyaspartic offers a higher-performing product and better long-term value.

Conclusion

If you are still searching for the best garage flooring for your garage or studio, you can also check other flooring options. So stop suffering on your floor or compare epoxy garage floor coverings and start enjoying a beautiful, durable arena. Therefore, contact Manmachine Automotive at +91-9310000-356 today, and let’s settle that polyaspartic vs. epoxy question for your specific project!

FAQs

Q1. How soon can I use my garage again?

You can often pull your cars on a polysapartic floor covering within 24 hours, which can completely turn the multi-day wait for the epoxy flooring of the garage.

Q2. Which floor will not crack or peel?

Polyspartic vs. Epoxy is an easy option as Polyspartic is flexible and moves with your concrete, making it better than cracks and chips.

Q3. Will the sun ruin the colour of my floor?

Yes, UV rays make traditional epoxy yellow and fade, but the advanced chemistry of polysapartic ensures that the colour lasts forever.

Q4. Why is polysapartic considered the best garage flooring?

It provides a complete package, incredible durability, UV stability, and motion beds, eliminating the need for the best long-term garage floor.

Q5. Is the additional cost of polypartic worth it?

Absolutely; While the starting value is high, you save money by repeating and avoiding the necessary epoxy.

Q6. What is one thing that actually sets up polyspartic apart from epoxy?

Compare epoxy garage floor coatings. One of the largest advantages is the ability to install a high-quality, lasting floor.

0 Comments